Cold Extrusion Type Beef Stick Extruding Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | ISO CE |

| Model Number: | MK126 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | USD 18000 /SET |

| Packaging Details: | packs the machine with export standard fumigation wooden cases, which is strong ans suitable for long-distance and multi-times loading & unloading by forklift. |

| Delivery Time: | 35-45 days |

| Supply Ability: | 10 set /per month |

|

Detail Information |

|||

| Material: | SUS | Capacity: | 200kg/hr. |

|---|---|---|---|

| Power: | 43KW | Workers Needed: | 2 WORKERS |

| 1.Delivery Time: 45 Working Days: | 45WORKING DAY | Certification: | CE |

| Product Name: | Cold Extrusion Type Beef Stick Extruding Machine | Working Way: | Cold Extrusion |

| Highlight: | pet food processing line,pet food processing equipment |

||

Product Description

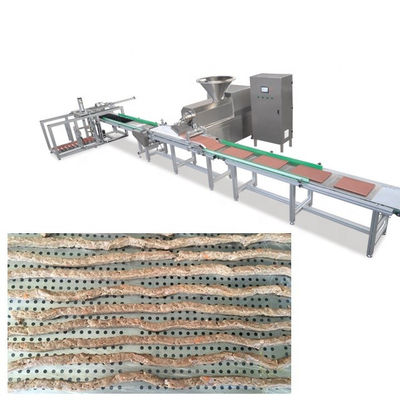

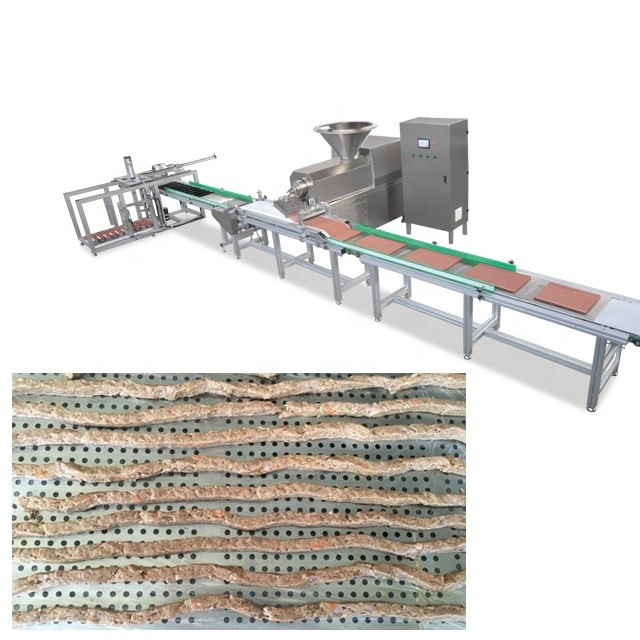

Cold Extrusion Type Beef Stick Extruding Machine

![]()

1. Auto traying system

Automatic tray system mainly is used for providing continuous individual tray to meat strip machine. To make products which produced by meat strip machine be cut according to tray’s dimension and automatically enter into tray, it is convenient for subsequent baking link . It can automatically pick and place tray through mechanical arm, equipped with tray store. With very high auotmation, can heavily save cost and manual labor intensity .Two layers belts design, meat strip comes on upper belt, and trays comes on nether belt. Top quality photoelectric sensors ensure meat strip and tray exactly matches each other, precisely length cutting control, labor saving, suitable for high standard meat strip producing. Whole system is composed by trays storage, trays picking up, trays conveying, auto cutter, etc.

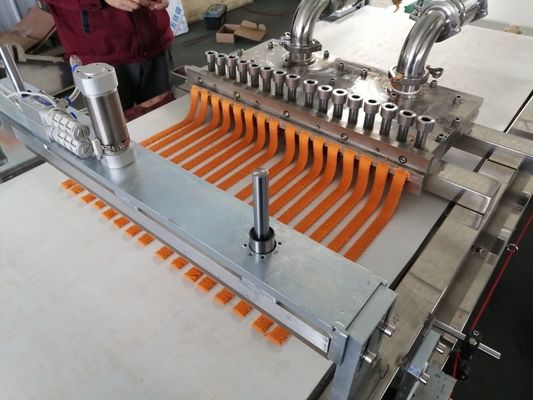

2. Meat strip extruding machine

Auto Meat Machine is equipment for producing pet treats, suitable for pet food without casing directly baked meat and meat products, widely used in pet food article beef, article chicken, beef rod, chicken rod production and processing. The procedure includes: Forming meat strip - Cutting as required length - Loading meat strip by tray automatically - Drying to required moisture- Cooling meat strip.

MK-126 meat strip extruding machine can extrude multi pieces of meat sticks. Different sizes and shapes can be made by changing the mold.Specially used to produce high content (max 100%) meat products.Patented design to produce meat strip with different shapes and sizes. Siemens motor, FATEK PLC, ABB or Schenider main electric parts.Stainless steel control cabinet, touch screen with friendly interface and fault display function.The screw adopts detachable structure, and has rust-proof treatment.The cylinder should be changed every 2-3 months. During production, cylinder pressure should be no more than 0.6Mpa.

Automatic tray system mainly is used for providing continuous individual tray to meat strip machine. To make products which produced by meat strip machine be cut according to tray’s dimension and automatically enter into tray, it is convenient for subsequent baking link . It can automatically pick and place tray through mechanical arm, equipped with tray store. With very high auotmation, can heavily save cost and manual labor intensity .Two layers belts design, meat strip comes on upper belt, and trays comes on nether belt. Top quality photoelectric sensors ensure meat strip and tray exactly matches each other, precisely length cutting control, labor saving, suitable for high standard meat strip producing. Whole system is composed by trays storage, trays picking up, trays conveying, auto cutter, etc.

2. Meat strip extruding machine

Auto Meat Machine is equipment for producing pet treats, suitable for pet food without casing directly baked meat and meat products, widely used in pet food article beef, article chicken, beef rod, chicken rod production and processing. The procedure includes: Forming meat strip - Cutting as required length - Loading meat strip by tray automatically - Drying to required moisture- Cooling meat strip.

MK-126 meat strip extruding machine can extrude multi pieces of meat sticks. Different sizes and shapes can be made by changing the mold.Specially used to produce high content (max 100%) meat products.Patented design to produce meat strip with different shapes and sizes. Siemens motor, FATEK PLC, ABB or Schenider main electric parts.Stainless steel control cabinet, touch screen with friendly interface and fault display function.The screw adopts detachable structure, and has rust-proof treatment.The cylinder should be changed every 2-3 months. During production, cylinder pressure should be no more than 0.6Mpa.

|

Machine

|

Auto meat strip machine

|

|||

|

Capacity

|

200-300kg/hr

|

|||

|

Air source

|

0.5-0.8Mpa

|

|||

|

Air Comsumption

|

90L/min

|

|||

|

Quantity of Placing Tray One Time

|

30pcs

|

|||

|

Weight

|

3000kg

|

|||

|

Power

|

25 kw

|

|||

|

Dimension

|

8630x3570x685mm

|

|||

Machine pictures and parameter

For the meat sticks machine, the main parts is extruder, which use cold extrusion technology, no heating when do extruding.

Air source: 0.5-0.8 Mpa Air Comsumption: 90L/min Tray size (customized): 49x95cm Quantity of Placing Tray One Time: 20-30pcs (depends on tray thickness)

Extruder

Capacity: 200-300kg/hr Cylinder pressure: 0.4-0.5Mpa Power: 22kw Mold Surface Size: 700X325X80mm Dimension: 1200 x 1300 x 2000mm

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory

|

|

Showroom Location

|

Canada, Turkey, United States

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Motor

|

|

Condition

|

New

|

|

Place of Origin

|

SHN

|

|

Brand Name

|

|

|

Application

|

Dog

|

|

Voltage

|

380V 50Hz 3pha, customized

|

|

Power

|

25kw, as per capacity

|

|

Weight

|

2000KG

|

|

Dimension(L*W*H)

|

1200 x 1300 x 2000mm

|

|

Warranty

|

1 Year

|

|

Product name

|

Soft Treats Cold Extrusion Meat Strip Machine

|

|

Function

|

cold extrusion to make meat strips

|

|

Machine material

|

SS

|

|

Capacity

|

200kg/h

|

|

Motor

|

Siemens or Leadgo

|

|

Processing Types

|

Cold extrusion

|

|

Raw material

|

meat or powder

|

|

Mold Surface Size

|

700X325X80mm

|

|

Screw diameter

|

126mm

|

|

Screw Material

|

38crmoal

|

Want to Know more details about this product