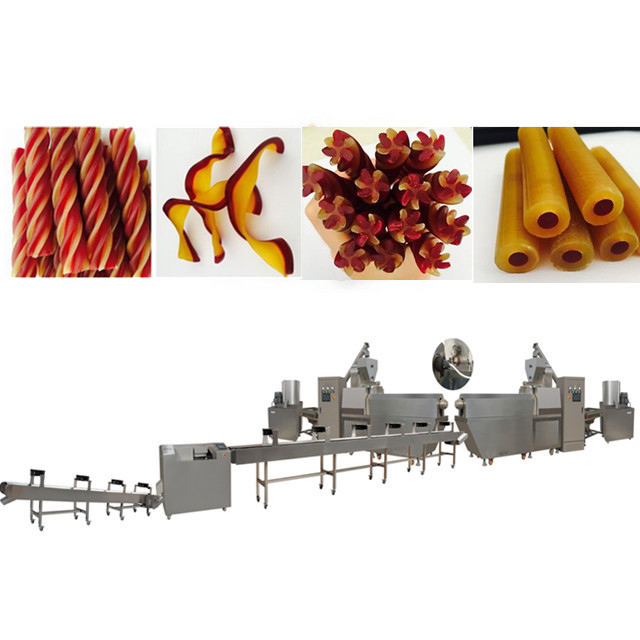

Colorful Dog Treats Making Machinery , Pet Feed Snacks Extruder Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | MIKIM |

| Certification: | CE ISO9001:2008 |

| Model Number: | MK-100/MK-300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD 28000~ USD 35000 |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 45 working days after receiving the down payment |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Condition:: | New | Model Number:: | MK-100/MK-300 |

|---|---|---|---|

| Application:: | Dog Snacks/ Pet Treats | Brand Name: | MIKIM |

| Material: | SUS304 | Motor: | WEG Motor With 3 Year Warranty All Over The World |

| PLC & Touch Screen: | Simens | Electric Parts: | ABB Or Schneider |

| Highlight: | Colorful Pet Food Production Line,SUS304 Dog Food Manufacturing Equipment,Colorful Dog Treat Making Machinery |

||

Product Description

Colorful Dog Treats making Machinery pet feed snacks extruder machine

![]()

1.Introduction:

1, Double Color Dog Treats Machinery or we call pet dog snacks machine.

2, Focuses on the production of feeds for animals with a high emotional value but low economic usefulness, apart from the aspect of breeding.

3, Nonetheless, balancing the components and gentle processing are at the center of the related quality considerations.

4, Double Color Dog Treats Machinery is therefore increasingly proving to be the right tool for modern Pet food. A complete feed, fed as a diet over a prolonged period of time, must ensure the vitality of the animal and prevent deficiencies.

5, Double Color Dog Treats Machinery is quite a challenge to the feed manufacturer in terms of the selection and composition of the raw materials, their optimal processing, and effective quality assurance.

6, Dog and cat snacks foods constitute the biggest market segment.

7, Feed for fish, high-grade complete feeds capable of maintaining the health even of exotic species in aquariums over prolonged periods of time, sinking or floating feed.

2.Materials: adopts corn flour, bone meal, fish meal as raw materials

3.Capacity: 100kg/h 200kg/h

4.Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

5.Process and follow chart

Mixer---Screw conveyor--- Single screw extruder---Cooling machine---Cutting machine--- Hoister

6.Technical Parameters

| Model | Capacity | Power | Dimension | Worker needed |

| MK-100 | 100-150kg/hr | 81kw | 18x5x3m | 2-3 |

| MK-300 | 200-260kg/hr | 95kw | 20x5x3m | 2-3 |

In order to increase the protein and other nutrients for our pet,Automatic dry dog pet food machine/processing line use meat powder,grains,beans and vegetables as raw materials to produce pet food with new shape, unique taste to let them live healthier.

1. Mixer blending all ingredients like corn flour,soybean flour, fish meal, bone/meat meal, water according to the accurate formula to make dry floating & sinking fish feeds , pet dog cat feed pellets with various daimeter 1mm, 1.5mm, 3mm, 5mm, 8mm, 10mm, 15mm, 20mm, etc.

Fish Feed Pellets Floating Time: 24 hours after baked dry completely with oil coated, also healthy for fish body growing, especially for salmon tilapia,catfish,trout,etc

2. Extrusion will male all materials cooking extrusion under the high temperature & pressure insde of the extruder barrel, with twin-screw high speed rounding. Then shaping the feeds into the fixed shape .

3. Drying processing we make sure every single feed pellets completely dry with our drying ovens which has the specially design hot air recelying system, supports electric/oil/gas/steam power resource type only suitable and cost saving for your local power conditions.

4. Flavoring line can be supply the feeds with oil , healthy for fish or other animals digestive absorption

Also can be added some other vitamins, minerals.

5. Cooling & packing, our package machine can be various 0.5-50kg/bag, range packing weight for your different markets needs, longer shelf life for final feed prodcuts.

![]()

![]()