Patent automatic dog food maker machine for meat strip dog treats with CE

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-126 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 45 working days after receiving the down payment |

| Payment Terms: | T/T, L/C, Western Union, D/A |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Material: | SUS304 | Type: | Automatically |

|---|---|---|---|

| Usage: | Meat Strips Dog Treats | Warranty: | 1 Year |

| Capacity: | 300~500kg Per Hour | Power: | 12kw |

| Dimension: | 14*6*3m | Worker Needed: | 2~3 Workers |

| Highlight: | pet food processing line,pet food processing equipment |

||

Product Description

MIKIM is an ISO9001 certified company specializing in pet food machinery and related packing machine since 1998, and all the machines are CE approved. machine runs in more than 40 countries including USA, Brazil, Uruguay, Suriname, Paraguay, Peru, Columbia, Argentina, Australia, Russia, Germany, Belarus, Latvia, Estonia, UK, Moldova, Holland, Italy, Hungary, Spain, Portugal, etc.

With more than 18 years’ experience and technology accumulation, we’d like to offer the best after-sales service to all of our customers.

Should you have interest in any project below, please feel free let us know, from our experience, the following items have very big demand potential, and it increases very quickly, we expect to have more communication and cooperation in near future.

![]()

Our current business includes:

| 1. | Dry Pet (Fish) Food Processing Line |

| 2. | Pet Treats (Dog Snacks) Processing Line |

| 3. | Pet Treats Injection Molding Machine |

| 4. | Pet Biscuit Processing Line |

| 5. | Rawhide Bone Pressing Machine |

| 6. | Meat Strip Machine |

| 7. | Cereal Bar Forming Machine |

| 8. | Relative Packing Machine (vertical packing machine, Doypack packing machine, flow pack etc.) |

Product Application

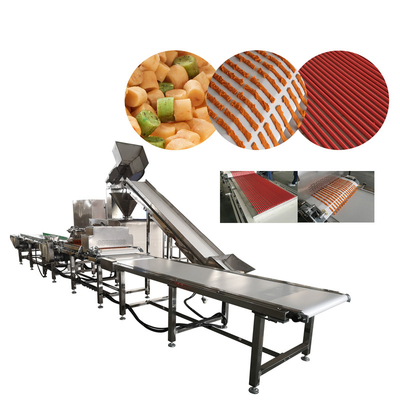

Natural Ingredients Delicious Chicken Breast Meat Strips Dog Treats Processing Line is an auto processing line can produce dog treat type meat strip. It combines two processing lines into one. With different moulds, various shapes can be made, such as strip, stick, screw shape, etc. Also, we can provide all kinds of recipe to make different tastes to full the demands of pet both for nutrition and chewing hobby.

Flow Chart:

Forming --- Pre-cutting --- Loading --- Drying --- Cutting --- Packing

Main Features

| 1. | Motors are from WEG, Germany, which has 3-year world-wide guarantee; |

| 2. | Electric parts are from ABB or Schneider, easy to find replacments at local market; |

| 3. | PLC and touch screen are from Siemens, Germany to realize easier operation and less labor quantity; |

| 4. | While faults occurred, relevant information will be displayed on touch screen, easy to settle the problem; |

| 5. | Control cabinet has 24V safe voltage (not 220V), which could protect the operator even electric leakage occurred; |

| 6. | Three kinds of protectors to keep machine and operator safe: over-current protector, over-voltage protector and over-heat protector; |

| 7. | All the cover body, mesh belt and parts touching with materials or final products are made by stainless steel 304. |

Technical Parameters

| Output | Power | Required Worker | Voltage / Frequency | Dimension |

| 300-500kg/hr | 12kw | 2~3 | 380V / 50Hz | 15 x 6 x 3m |

Commissioning Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

![]()