Pet Food Production Line Commercial meat / fish / beef jerky making / forming machines

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 35 working days after receiving the down payment |

| Payment Terms: | T/T, L/C, Western Union, D/A |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Material: | SUS304 | Usage: | Jerky Treats Dog Snacks |

|---|---|---|---|

| Warranty: | 1 Year | Capacity: | 300~500kg Per Hour |

| Power: | 18kw | Dimension: | 4.3*0.9*2m |

| Worker Needed: | 1~2 Workers | Original: | China |

| Highlight: | pet food processing line,pet food processing equipment |

||

Product Description

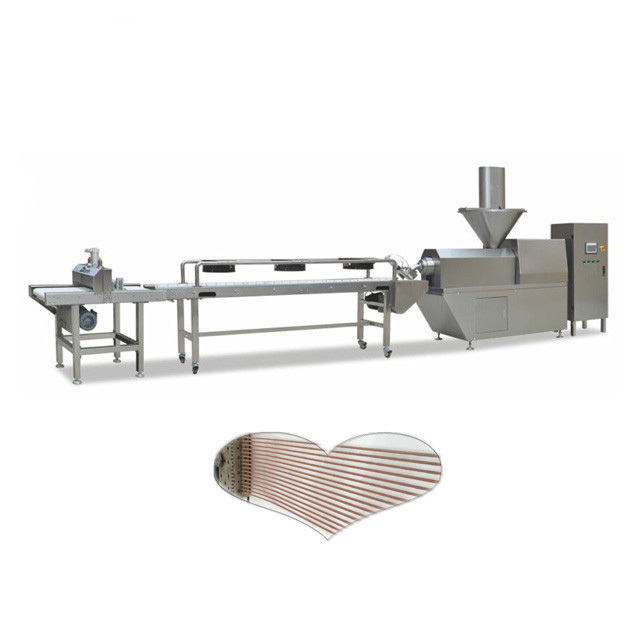

Commercial meat /fish / beef jerky making/forming machines made in china

Auto Meat Strip Processing Line is an auto processing line can produce dog treat type jerky treats. With different moulds, various shapes can be made, such as strip, stick, screw shape, etc. Also, we can provide all kinds of recipe to make different tastes to full the demands of pet both for nutrition and chewing hobby.

Main Features

| Application: | Meat Foods. |

|

Machine Material:

|

Stainless Steel |

| Type: | MK-200 |

| Capacity: |

300-500kg/hr

|

| Certification: | CE & ISO9001 |

| Place of Origin: | China. |

| Motor: | WEG, Germany |

| Electric Parts: |

ABB, Switzerland or Schneider, France

|

| PLC and Touch Screen | Siemens, Germany |

|

Bearing:

|

NSK, Japan |

| Voltage / Frequency: | Customized |

| Operation: | PLC screen control. |

| Payments: | T/T, L/C, |

|

Delivery time:

|

35 working days.

|

| 1 |

Main Motor from SIEMENS(CHINA), ensure its Powerful Extrusion and Excellent Performance. |

| 2 |

The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating. |

| 3 |

Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely. |

| 4 |

Cutting knife fixed in the die head seat, rotary cutting by V-belt drive. |

| 5 |

The gearbox has automatic lubrication function, with extends gear life. |

| 6 |

The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barreland screw, when roasting or replacing of materials. |

Commissioning & After-sales Service

| 1. | We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc. |

| 2. | After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service. |

| 3. | 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time. |

| 4. | Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line. |

| 5. | It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service. |

![]()