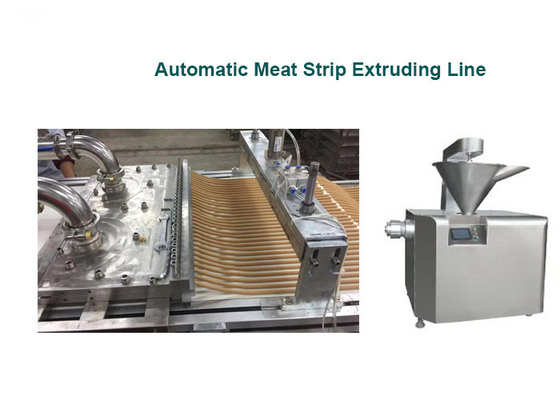

Jerky Treats Dog Food Extruding Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-126 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 45 working days after receiving the down payment |

| Payment Terms: | T/T, L/C, Western Union, D/A |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Material: | Stainless Steel | Usage: | Meat Strips Dog Treats |

|---|---|---|---|

| Warranty: | 1 Year | Capacity: | 300~500kg Per Hour |

| Power: | 20kw | Dimension: | 14*6*3m |

| Worker Needed: | 2~3 Workers | Original: | Jinan |

| Highlight: | pet food processing line,pet food processing equipment |

||

Product Description

Features & Advantages

MK-126 meat strip extruding machine can extrude multi pieces of meat sticks. Different sizes and shapes can be made by changing the mold.

Ø Specially used to produce high content (max 70-80%) meat products.

Ø Patented design to produce meat strip with different shapes and sizes.

Ø Stainless steel control cabinet, touch screen with friendly interface and fault display function.

Ø The screw adopts detachable structure, and has rust-proof treatment.

Technical Parameters

| Output | Power | Required Worker | Voltage / Frequency | Dimension |

| 300-500kg/hr | 11kw | 2~3 | 380V / 50Hz | 15 x 6 x 3m |

Commissioning Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After delivering machines to the client’s factory, we start to apply for the Visa to the client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrive at your factory, our engineers are ready to start the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production in the shortest time.

4. Our engineers have a responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning

service, and we supply a 1-year guarantee from the date of completion of commissioning service.

6. The engineer’s round-trip flight tickets, accommodation, and daily salary of USD 100 are on the client’s account.