Dog Care Teeth Chewing Snacks Pet Treat Machine 380V Or Customizable Voltage

Product Details:

| Place of Origin: | China |

| Brand Name: | Mikim |

| Certification: | CE ISO9001:2008 |

| Model Number: | MK-100 / MK-300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD 28000~ USD 35000 |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 60 working days after receiving the down payment |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Condition: | New | Place Of Origin: | China (Mainland) |

|---|---|---|---|

| Application:: | Dog Treats | Voltage: | 380V Or Customizable |

| Power: | 35-100KW | Warranty: | 12months |

| Payment Terms: | T/T OR L/C | Material: | Stanless Steel |

| Capacity: | 100-150kg Per Hour , 200-250kg Per Hour | ||

| Highlight: | pet food processing machinery,dog food manufacturing equipment |

||

Product Description

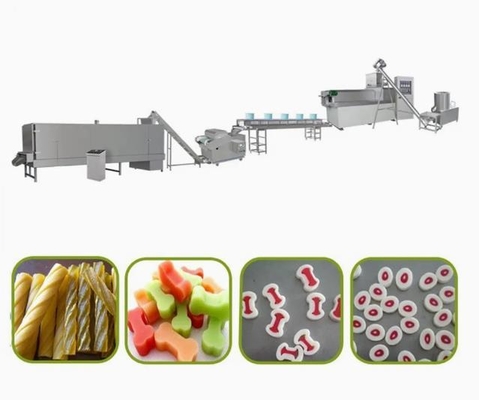

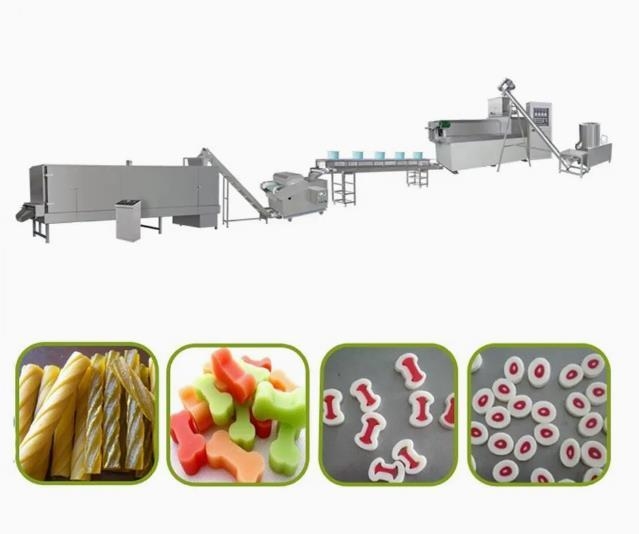

Healthy Dog Teeth Chewing Snacks Treats Dog Food Making Machine

![]()

Pet Dog Meaty Treat Cold Extrusion Machine Lecithin Dog Snacks Machine Dog Food Extrusion Machine flow:

Raw material preparation→Mixing raw material→Conveying→Extrusion→Conveying→Drying→Screening→Oil spraying→Flavoring→PackingPet Dog Meaty Treat Cold Extrusion Machine Lecithin Dog Snacks Machine Dog Food Extrusion Machine setting:

Mixer→Conveyor→Extruder→Wind conveyor/hoister→Multi-layer dryer→Sifter→Hoister→Oil sprayer→Single/double roller→Packing machine

In some cases,the production need to mill, and can adopt:Mixer→Conveyor→Extruder→Crusher→Packing machine

Formation of Pet Dog Meaty Treat Cold Extrusion Machine Lecithin Dog Snacks Machine Dog Food Extrusion Machine :

1 Mixer:There are 3 machine model numbers to choose from base on the production capacity.

2 Conveyor:To convey raw materials to the extruder machine

3 Extruder machine: To choose DSE model extruders base on the production capacity requirement from 100kg per hour to 3ton per hour. The raw material include corn powder, cereal powder, soybean powder, shrimp powder and so on. Size of the pellet depends on the moulds. The pellet size our machine can produce are 0.5mm, 1mm, 2mm, 3mm, 4mm, 5mm,6mm.

4 Hoister: Convey the fish food to the dryer, the height of the hoister depends on the dryer.

5 Multilayer dryer:Electric dryer, controlled by control box, temperature range 0-200ºC.Inside is stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6 Sifter:To remove scrap

7 Flavoring line: To spray oil and phagostimulant, the equipment are: single roller, double roller, round roller, eight-angle roller. Varies depends on the different production line setting, to spray oil to the surface of the product and make it even.

8 Cooling conveyor: To lower the product temperature in order to pack it easily.

9 Sifter: To remove the wasted material and ensure quality, meanwhile to ensure the reuse of materials.

10 Packing machine: Manual and automatic packing machine.

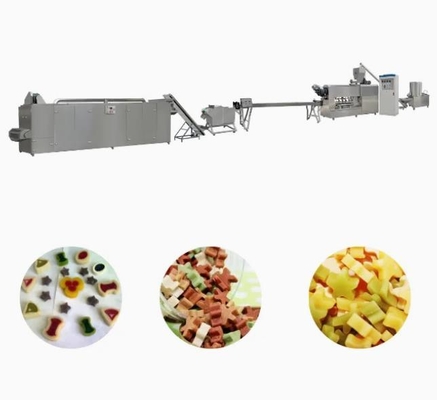

Technical parameter of Full Automatic Double Color Pet Dog Chew Food Pellet Making Machine :

| Model | Installed power | Real power | Output | Dimension |

| MK100 | 70KW | 40KW | 100-150kg | 22000*1200*2200mm |

| MK110 | 90KW | 50KW | 200-240kg | 25000*1500*2200mm |

| MK130 | 120KW | 100KW | 400-500kg | 30000*3500*4300mm |

![]()

![]()

![]()

Want to Know more details about this product