Large Capacity Output Puff Snack Machine , SS304 Rice Puff Making Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE |

| Model Number: | MK-65/70/85/90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, which are suitable for long-term trip and multi-times loading & unloading by trucks. |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Condition: | New | Dimension(L*W*H): | 2150*1500*2300 |

|---|---|---|---|

| Voltage: | 380v, 50hz, 3phases (adjustable) | Warranty: | 12 Months |

| Applied: | Corn Puff Snack Extruder | Material: | SS304 |

| Manual: | English Version | Capacity: | 120-150kg/h,200-250kg/h,400-500kg |

| Highlight: | grain puffing machine,corn puff extruder machine |

||

Product Description

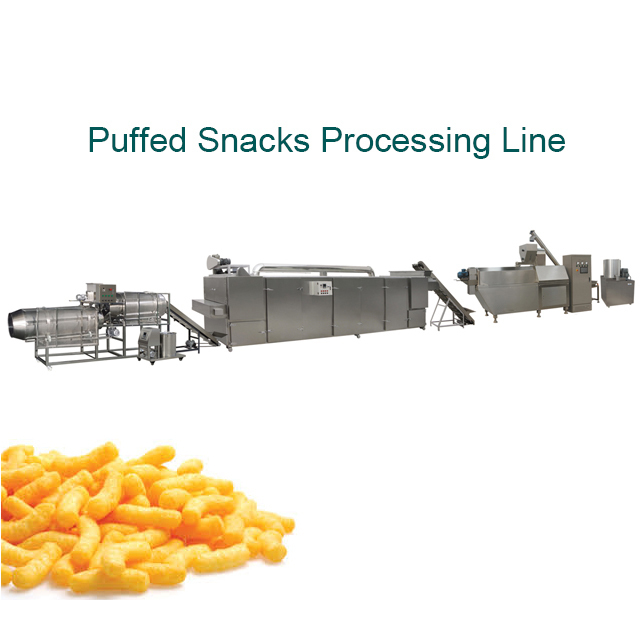

Large Capacity Output Puff Extruder Machine , rice puff making machine

1. Brief Description for corn snacks extruder machine

Direct puff snack process line uses wheat flour, maize meal and others as the main raw materials, by taking the advantage of pressure difference between inside and outside in a high temperature and high pressure condition to produce a variety of puff snack which is popular in the market, such as globular, rolls, crispy stick, rings etc. By changing moulds and assistant equipments, it can also produce nutritional powder, grain gruel and many other leisure snacks in different shapes. This automatic process line is of leading level for its superior characters, such as, "applied to many materials, convenient operation and maintenance, low power consumption, high output".

2. Descriptions of Product

1. Use Switzerland technology and make in China.

2. Direct-connected-drived is used for motor and distribution box,by which enerty could be saved. 3. Adopt original imported bearing groups with high loads.

4. Fully-enclosed discharging, forced feeding,large feeding scope.

5. Raw material pre-treatment system with long-type modulator, big storage tank, automatic

water- injection, etc.

6. Screw rod is made of high abrasion proof material, hardness is higher than HRC=55, long

service life.

7.Screw rod is assembled in brick pattern. It can be assembled freely as per different raw material

and products.

8. Infrared stainless steel ring is used for machine barral heating. Temperature in each area can

be adjused separately. Automatically cycling cooling system. Temperature control is correct.

9. Rotary cutting device adopts suspension mould seat (for knives). Linear bearing knives

adjustment device. safely, correctly and speedily

Equipment Configurations

- Flour Mixer: Stir mixed raw materials evenly with a certain amount of water. Choose different GY flour mixer model according to different output requirements.

- Spiral Conveyor: Convey stirred raw materials into feeding hopper of extruder.

- Extruder: Select different GY extruder model based on clients’ raw materials and output capacity requirement. With the help of special control cabinet, extruder is able to extrude the raw material under different temperature & pressure, and produce puffed products. The shapes of products can be changed by changing the modules in extruder.

- Multi-layer Drying Oven: Dry semi-finished products. It is the most common dehydration plant for puffed food. It includes a belt dryer and some in-built heating devices to carry out drying by means of electricity, vapor, diesel or gas. The drying temperature and drying time can be controlled.

- Flavoring Line: Select square flavoring machine, single-roller flavoring line or dual-roller flavoring line, based on output and product properties. Single-roller and dual-roller flavoring line combine the functions of flavoring with seasoning and oil injection together.

Characteristics

- Various models to meet different output capacity requirements.

- Flexible configurations to meet different produce, budget and workshop layout requirement.

- Vast raw material range to produce different final products by only one production line.

- Different shapes and appearances of final products can be made by changing different modules in extruder.

- High automation and accurate control system to save labor cost and improve the quality of final products.

- Independent temperature control system is able to realize zone temperature control, electronic induction, accurate & visual digital display.

- Feeding system without material returning. It is unnecessary to clean barrel and screw in case of restarting or material replacement.

- Screw adopts high-performance nitride alloy steel with strong wear-resistance and longer service life.

- Food-grade stainless steel. Neatness and easy clean.

3.Technical Parameters

| model | installed power | power consumption | output | size |

| MK65 | 81.5kw | 53kw | 120-150kg/h | 21000x1200x2200mm |

| MK70 | 116kw | 76kw | 200-250kg/h | 23000x1500x2200mm |

| MK85 | 181kw | 117kw | 400-500kg/h | 28000x3500x4300mm |

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and

wear-resting. And it has good self-cleaning ability and does not need to discharge or

clean the barrel and screw, when roasting or replacing of materials.

2. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel

coating.

3. Radiator is increased on driving part for forced cooling effect, and it ensures extruder

operate safely.

4. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

5.The gearbox has automatic lubrication function, with extends gear life.

6. Main Motor from SIEMENS(CHINA), ensure its Powerful Extrusion and Excellent

Performance.

Why You Must Choose Us

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

2. Double Axis Differential Conditioner, Available for Steam, Pre-cooking and High Efficient.

3. Linear Slide Face Cutting System, Strong Power, Variable Frequency Speed and Large Output,

4. Unique Designed Square Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

5. Modular Circular Groove Screws, available for Different Extrusion Rate Applications.

6. Steam Heating System, ensure the Most Efficient, Continuous and Stable Heating Effects.

7. World-famous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect.

8. Main Motor from SIEMENS(CHINA), 90KW, ensure its Powerful Extrusion and Excellent Performance.

Quick Details

Condition: New

Place of Origin: China (Mainland)

Brand Name: MIKIM

Model Number: MK65/MK70/MK85

Application: snack food / nutrition food/food

Power(W):30-150 kw

Dimension(L*W*H): 21000x1200x2200mm

Certification: CE/ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

Packaging Details: Suitable for export wooden box

Delivery Detail: About 35 days after receiving the down payment

![]()

![]()

![]()