Twin Screw Food Fully Automat Shrimp Fish Feed Pellet Processing Machine Fishing Food Extruder Floating Fish Feed Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | MIKIM |

| Certification: | CE |

| Model Number: | 65,70,75,85,95,120,136 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | $1500.00 - 9500.00/ Set |

| Packaging Details: | packed by wooden export package or loading by container |

| Delivery Time: | 7-10 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 sets per month |

|

Detail Information |

|||

| The Color: | Silver | Applicablematerial: | Pet Food Raw Materials (corn, Meat Meal, Fish Meal, Etc.) |

|---|---|---|---|

| Power: | 37 KW | After Sales Service: | Full Life |

| Material: | Stainless Steel | Machine Size: | 2 * 2.8 * 1.2 |

| Highlight: | twin screw shrimp feed extruder,floating fish feed pellet machine,automatic pet food processing extruder |

||

Product Description

Twin Screw Food Fully Automatic Shrimp Fish Feed Pellet Processing Machine

New business small manufacturing ideas extrusion flat feed food extruded fish pellet feed grinder floating fish pellet machine

Introduction

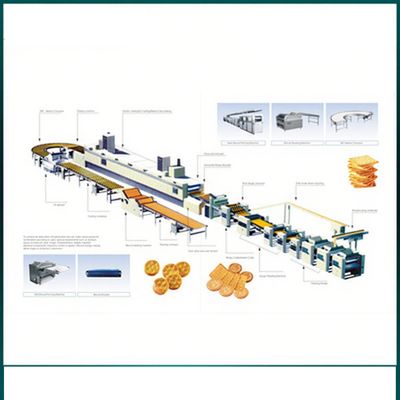

The fish feed processing line is suitable for breeding different types of fish, from small-scale fish farming to large-scale commercial operations. It accommodates various fish species including tilapia, catfish, trout, and salmon. The main components include a flour mixer, twin screw host, oven, and seasoning system. The mixing machine thoroughly blends raw materials and nutrients, while the twin screw host compresses the mixture. The extruded fish feed is then dried in an oven to reduce moisture content and extend shelf life.

Production Flow Chart

Mixer → Conveyor → Twin Screw Extruder → Vibrating Machine → Air Blower → Drying Machine → Hoister → Flavoring Machine

Technical Specifications

| Model (Electric) | Capacity (kg/h) | Main Power | Cutting Blade Power | Cutting Power | Modulated Power |

|---|---|---|---|---|---|

| 65 | 250-300 | 22KW | 1.5KW | 1.5KW | 3KW |

| 70 | 500-600 | 45KW | 1.5KW | 1.5KW | 3KW |

| 75 | 800-1000 | 55KW | 1.5KW | 1.5KW | 3KW |

| 85 | 1200-1500 | 90KW | 3KW | 2.2KW | 5.5KW |

| 95 | 2000-2500 | 110KW | 3KW | 3KW | 11KW |

| 120 | 3000-4000 | 160KW | 5.5KW | 3KW | 15 + 7.5KW |

| 136 | 5000-6000 | 200KW | 7.5KW | 5.5KW | 22 + 7.5KW |

Key Features

- Automated feeding system - Automatically transfers fish feed from hopper to extruder

- Variable speed control - Enables precise temperature and pressure adjustments for optimal performance

- Temperature sensing - Integrated sensors in barrel and die provide feedback for improved operation

- Feed-material selection - Processes various materials including cereals, nuts, oils and fats

- Pelletizing capabilities - Pelletizing head ensures uniform pellets with greater surface area for improved digestion

Production Capabilities

Our automatic line can produce 1-20mm floating and sinking fish feed, shrimp feed, aquatic feed, and prawn feed by adjusting formulas and molds.

Tianjin Mikim Technique Co., Ltd.

Mikim Machinery is a high-tech enterprise integrating scientific research, design, manufacture, installation, commissioning, and after-sales service. With 35 years dedicated to feed machinery design and production, we hold certifications including CE and ISO. Our expertise spans two main fields: feed pellet machine production lines (hammer mill-mixer-conveyor-feed pellet machine-cooling & vibration system-packing and sealing) and feed extruder production lines (mixer-twin screw extruder machine-dryer-drum seasoning machine-cooling towers-packing machine). We produce high-quality, competitively priced equipment exported worldwide, enjoying a strong reputation and comprehensive after-sales service system to address all customer needs.

Want to Know more details about this product