Auto Puff Snacks Processing Line For Ball Tube Stick Ring

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE |

| Model Number: | MK-65/70/85/90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, which are suitable for long-term trip and multi-times loading & unloading by trucks. |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Condition: | New | Dimension(L*W*H): | 2150*1500*2300 |

|---|---|---|---|

| Voltage: | 380v, 50hz, 3phases (adjustable) | Warranty: | 12 Months |

| Applied: | Corn Puff Snack Extruder | Material: | SS304 |

| Manual: | English Version | Capacity: | 120-150kg/h,200-250kg/h,400-500kg |

| Highlight: | SS304 Puff Snack Machine,150kg/h Puff Snacks Processing Line,Auto Puff Snacks Processing Line |

||

Product Description

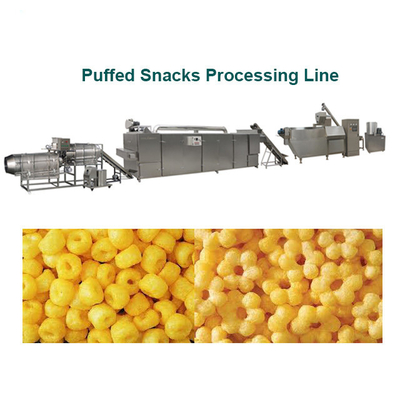

Auto Puff Snacks production line corn puff snack extruder for ball, tube, stick, ring available shape making

1. Description

Snacks Food Extruder/Puff Snack Food Machine

Brief Introduction: Puff Snacks Extruding Line can produce all kinds of extrusion products, such as snacks and breakfast cereal, etc. The raw materials can be maize, rice or wheat flour, etc. The performance and quality of Snacks Processing Line reaches the highest international level in its field. From feeding materials, extruding & inflating, core filling, shaping, roasting, cutting, oil spraying to finished products are done once time automatic. Extruder control is based on a programmable computer system which adjusts for optimal parameters according to different recipes, water content, pressure and temperature, allowing for simpler more dependable processing.

Machine

2. Raw materials' range for Puff snack food production:

Puffed Corn Snacks Food Production Chain

All kinds Cereals' powder(flour)

Snacks Food Extruder/Puff Snack Food Machine

3. Products:

Snacks Food Extruder/Puff Snack Food Machine

Variety shapes are available for ball, tube, stick, ring, fruit loop, car, bear,star, wheel and flower and heart shape by changing the mould in the extruder. We will design and make the moulds according to your requirement after the order.

Corn Snacks Puffing Machine

4. Capacity

Snacks Food Extruder/Puff Snack Food Machine

150kg/h, 250kg/h, 500kg/h

Corn Snacks Food Extruder

5. Flow chart

Snacks Food Extruder/Puff Snack Food Machine

Mixing system---Extruder---- -Roasting system----Flavoring system---Packing system(Optional)

Puffed Corn Snacks Food Production Chain

6. Power:

Snacks Food Extruder/Puff Snack Food Machine

3 phases electricity will be required, we will make the machines with the right motors, electrical elements according to the electricity in your place. (Could you please kindly let me know the Voltage and frequency in your factory in your inquiry? For example: It is 380V/50Hz in 3 phases and 220V/50Hz in single phase in China).

Puffed Corn Snacks Food Production Chain

7. Machines Materials:

Corn Snack Extrudeuse Machine

a. Screws: 38# CrMOALA

b. Parts where touch food: Food grade stainless steel.

Snack Food Extrudeuse Machine

8. Technical Parameters

|

Model |

Capacity |

Power |

Dimension |

|

MK-65 |

120-150kg/hr |

70kw |

22 x 5 x 3m |

|

MK-70 |

200-260kg/hr |

90kw |

24 x 5 x 3m |

|

MK-85 |

300-500kg/hr |

120kw |

30 x 5 x 3m |

Our services:

- Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

- Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.

- After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts;

![]()

![]()

![]()

![]()

Sample picture:

![]()