Singe Screw Dog Food Extruder Feed Pellet Production Line with CE ISO certificate

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE Certificate |

| Model Number: | MK-100/300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | wooden case, which is suitable for long-distance transportation, multi-time loading & unloading for fork trucks. |

| Delivery Time: | 45 work days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 SET/Year |

|

Detail Information |

|||

| Product Name: | Dog Chewing Food Machine | Power(W): | 145kw |

|---|---|---|---|

| Dimension(L*W*H):: | 30 X 5 X 3m | Condition: | Continuous & Automatic |

| Output: | 100kg/hr | After-sales Service: | Full Life |

| Moulds: | 6 Free Moulds | ||

| Highlight: | feed pellet extruder,dog food making machine |

||

Product Description

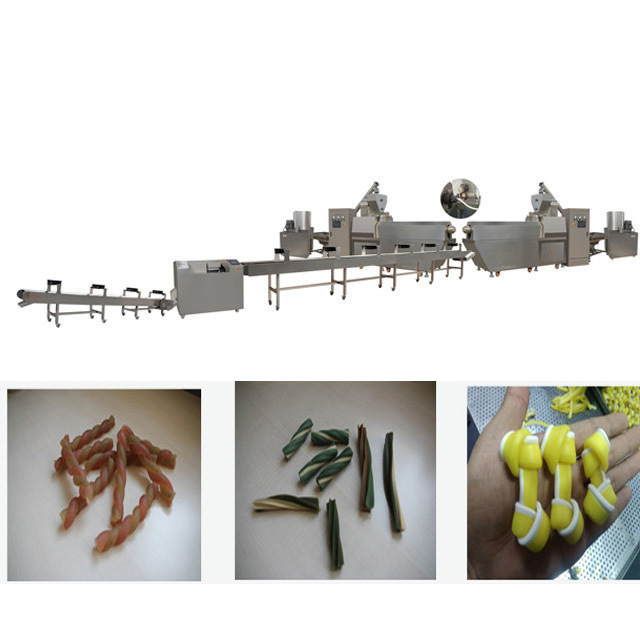

Dog Food Extruder/Dog food /Dog chew snack stick food processing line with CE ISO certificate

Introduction:

With our new technology of combination screws,our twin screw extruder production line is applied to produce

different pet food with various raw material and nutrient elements.The production technology parameters are controlled precisely.

Through extruding,the degraded protein is easy to absorbed.Meanwhile ,with relevant palatability supplementary project,

the production process can fulfill the chewing feel of pets.

Singe Screw Pet Treats Machine takes starch as raw materials with scientific configuration and was extruded from co-extrusion, it can be made into many kind of shapes such as stick,bone ect. This kind of food not only provide protein,fat,vitamin ,nutrition for dogs, but also satisfy the dog nature hobby. It has following features: strong teeth, clean mouth and teeth, good for diet. The products can be in many shapes, like twist, double colors, core-filling and so on.

Flow chart: Raw Material Mix – Screw Conveying – Extruding – Cooling – Cutting – Drying -- Cooling

![]()

Technical Parameters

Standard Configurations

| Item | Brand |

| Motor | WEG, Germany |

| Electric Parts | ABB, Switzerland or Schneider, France |

| PLC and Touch Screen (controls whole line, not one or two single equipment) | Siemens, Germany |

| Bearing | NSK, Japan |

| Materials | All the cover body, mesh belt and parts touching with raw materials or final products are SUS304 |

- Dog Chewing Food Machine can produce dog chew snacks and semi moist pet food.

- It combines two processing lines into one: pet snacks and semi-moist pet food.

- With different moulds, various shapes can be made, such as strip, stick, screw shape, etc.

- All kinds of perfectly shaped non-crumbing chew snacks in a variety of color combinations.

- Max. 3-color chew snacks can be produced.

- Various shapes can be made, such as strip, stick, bone, screw shape, etc.

- Many kinds of recipes to make different tastes to meet different market demands.

- Turnkey project provided, from raw materials to packing procedures, fully continuous and automatic.

- Fully stainless steel 304.

|

Output |

Installed Capacity |

Actual Capacity |

Workers Required |

Dimension |

|

100-150kg/hr |

66kw |

50kw |

2-4 workers |

10 x 5 x 3m |

MK-100 Single Screw Extruder serves to gelatinize flours and starches continuously and automatically. After dosing, the materials are worked by one screw composed by sectional modules for the following functions: forward and backward transport, mixing, feeding of additives, injection of liquids, de-gassing, cooking and forming.

1.PLC and 10” touch screen with friendly interface to control the whole line, not one or two single equipment;

2. While any parts got problems, the fault alarm will be shown on the touch screen;

3. Password can be set on the touch screen to avoid any misoperation by the workers;

4. The structure is made by carbon steel, and the cover body, mixing tank and all the parts in contacting with the raw material are made by stainless steel 304;

5. A wide range of products can be obtained in a variety of different ways, and can configure various dies simply and rapidly;

6.Two sets of Single Screw Extruder can work together to make double-color pet treats, also can connect Twisting Device for twist pet treats;

7. The use of a continuous automatic process provides greater production outputs than offered by traditional systems, with savings in energy and reduced management cost;

8. Automatic dosing unit for utilization with any type of flours and starches (the size should be 60-80 mesh);

9. The screw is all made by 38CrMoALA alloy, and the surface is being processed nitrogen treatment, so the hardness could reach 55hrc, which is hard and strong, and has longer service life;

10. Barrel is divided into 5 temperature zones, and each zone is controlled separately;

11. Auto-temperature control system; make the temperature controlling more direct viewing and the parameter more precise;

12. Equipped wit cooling system for cooling the barrel and screw;

13. Control cabinet has three kinds of protections: overload protection, overcurrent protection and overheat protection.

14.Nice appearance with streamline modelling.

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques;

Provide 1 year complete warrantee and lifetime maintenance service;