Puff Snacks / Corn Flakes / maize flakes making machine , corn flakes machinery

Product Details:

| Place of Origin: | China |

| Brand Name: | Mikim |

| Certification: | CE/ISO |

| Model Number: | MK-65 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 70000-100000USD/SET |

| Packaging Details: | wooden case |

| Delivery Time: | 40-50 working days |

|

Detail Information |

|||

| Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. | Material: | SS304 |

|---|---|---|---|

| Layout: | AutoCAD Format According To Client’s Workshop | Condition: | Continuous & Automatic |

| Processing Type: | Extrusion | Place Of Origin: | Shandong, China (Mainland) |

| Commissioning: | Provided | ||

| Highlight: | corn flakes making machine,maize flakes machinery |

||

Product Description

Puff Snacks / Corn Flakes / maize flakes making machine , corn flakes machinery

![]()

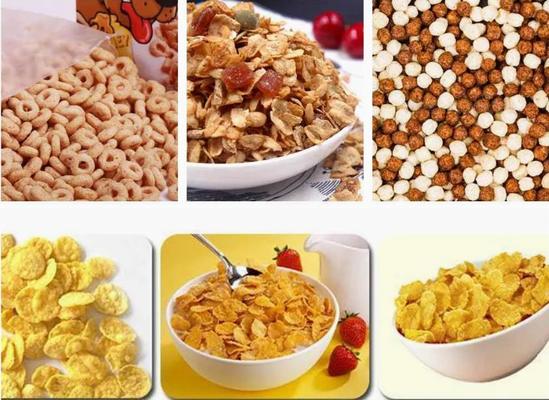

Corn Flakes Extruder Machinery For Sale produces corn flakes, cereals, and puff snacks similar to Kellogg and Nestle products.

CERTIFICATE

CE CERTIFICATE provided, which strictly meet CE standards and EU countries import policy.

ISO 9001 CERTIFICATE provided, which strictly meet ISO 9001 standards

Raw Material

- Corn puffed snack extruder For Sale Main raw material corn floue, wheat flour, rice powder, corn starch, potato starch, etc.

- All this raw material should be 60-80 mesh.

- No care about the moisture content and the strength of the raw material.

Features

Corn puffed snack extruder For Sale has complete circle for production of corn flakes, which has regular shapes and tasty taste.

Corn puffed snack extruder For Sale is continuous, automatic and economical process with an easily controlled production cycle.

Thanks to the particular process conditions, the finished product having long lasting crispness in milk due to minimal damage of the cereal's starch structure during processing.

End product exhibiting the best combination of texture, color and flavor base on an accurate control of the conditioning, drying and toasting stages of the process.

Unlimited choice of shapes and formulae for shaped cereal, fully automatic and continuous processing procedures.

Corn puffed snack extruder Sale is not just a combination of machines, but an integrated process starting with raw material feeding and ending at the packaging room.

Technical Parameters

| Model | Capacity | Power | Dimension |

| MK-65 | 120-150kg/hr | 120KW | 45 x 5 x 3m |

| MK-70 | 200-300kg/hr | 150KW | 56 x 5 x 3m |

![]()