3D Snack Pellet Machinery / Single Screw Snack Extruder Machine For 3D Pellets

Product Details:

| Place of Origin: | China |

| Brand Name: | Mikim |

| Certification: | CE/ISO9001 |

| Model Number: | MK-100, 300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | 35000-86000USD/SET |

| Packaging Details: | wooden case |

| Delivery Time: | 45-60 working days |

| Payment Terms: | T/T, L/C, D/P or Western Union |

| Supply Ability: | 99 sets per year |

|

Detail Information |

|||

| Features: | Continuous & Automatic | Condition: | NEW |

|---|---|---|---|

| Applied: | 3D Snack Pellet Machinery | Manual: | English Version |

| Capacity: | 120-150kg/h,200-250kg/h,400-500kg | Material: | SUS304 |

| Warranty: | 3 Year | Recipe & Formula: | Provide Free Of Charge |

| Highlight: | 3d snack pellet machinery,single screw snack extruder machine,3d snack extruder machine |

||

Product Description

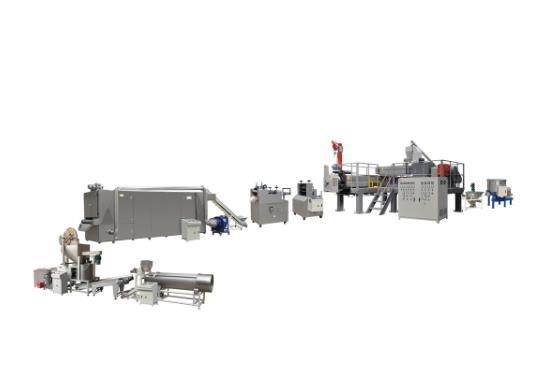

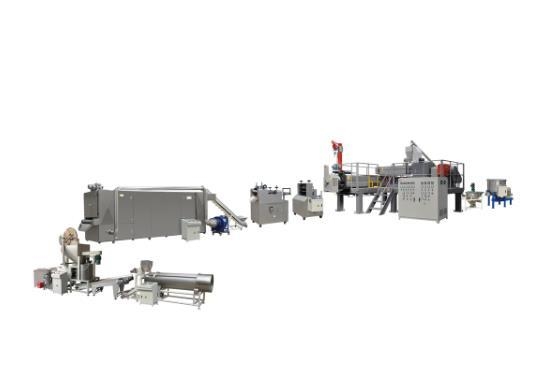

3D Snack Pellet Machinery/Snack Extruder Machine/Single Screw Extruder for 3D Pellets

![]()

Pellets Extruding Machine,Fry Snack Machine,3D Pellets Machine

![]()

We invite you to the innovation processes concerning "Triangle Chips". The lines have always been characterized by their innovative technical solutions and their high degree of reliability. 3D Snacks Extruding Line is for pellet production by single-screw extruder. 3D snacks can by different shapes, like triangle, round, hexagon, heart, xmas trees, diamond, etc. First, the materials are extruded to be a semi-manufactured dry product, made of dough, cooked opportunely using extrusion cooking technology, shaped and formed until reaching a humidity of less than 12%. This semi-manufactured product is extremely compact, (apparent density of 300-400 g/l, 10 times higher than that of the finished product) occupies little space and can be easily preserved for over a year in normal environment conditions, without particular packaging. The pellet can be fried or expanded to obtain a finished food product.

Standard configurations

Flour Mix – Screw Conveying – Extruding – Shaping – Cooling – Drying – Frying – Flavoring – Cooling

Various raw materials can be chosen

The raw material can be corn flour, maize starch, corn flour, potato powder, potato starch, cassava starch or their mixture, etc.

Technical Parameters

| Output | Installed Capacity | Voltage / Frequency | Dimension | Workers Required |

| 100-150kg/hr | 240kw | 380V / 50Hz | 38 x 5 x 3m | 4-6 workers |

![]()

Spare Parts List

| No. | Name | Quantity | No. | Name | Quantity |

| 1 | Asbestos glove | 1 | 11 | Shaping knife | 4 |

| 2 | Plum-blossom shape spanner | 1 | 12 | Temperature control meter | 1 |

| 3 | Mould strip stick | 1 | 13 | Leather belt | 3 |

| 4 | Mould strip plate | 1 | 14 | Small relay | 2 |

| 5 | Moulds | 6 | 15 | Knob switcher | 2 |

| 6 | Heating circle | 4 | 16 | Indicator | 2 |

| 7 | Relay | 2 | 17 | Ammeter | 1 |

| 8 | Alternating contactor | 2 | 18 | Heating tube | 2 |

| 9 | Inner six angle spanner | 1 | 19 | Thermocouple | 1 |

| 10 | Rotary cutter | 4 | 20 | Voltmeter |

1 |

Service

| 1. |

Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried; |

| 2. |

During Production: Timely updates the machine status for customer to ensure delivery time, and quality |

| 3. |

After Production: Machine testing video and photos will be provided for inspection, if the customer can't come; |

| 4. |

Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller; |

| 5. |

Installation & Training: Providing professional and expert technical engineers to supply the training and installation service. |

| 6. |

After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts; |