Automatic Corn Flakes processing line&roasted corn flakes processing line/corn flake making machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-65/70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, |

| Delivery Time: | 45 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Product Name: | Fully Automatic Corn Flakes Processing Line , China Supplier High Quality Breakfast Cereals Corn Flakes Production Line | Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. |

|---|---|---|---|

| Condition: | New | Layout: | AutoCAD Format According To Client’s Workshop |

| Manual: | English Version | Key Words: | Automatic Corn Flakes Processing Line&roasted Corn Flakes Processing Line/corn Flake Making Machine |

| Highlight: | rice flakes making machine,maize flakes machinery |

||

Product Description

Automatic Corn Flakes processing line&roasted corn flakes processing line/corn flake making machine

![]()

Twin Screw Extruder Corn Flakes Breakfast Cereal Production Line can produce corn flakes which is one kind of nutritional convenient food which is produced by this process line, using flour as basic material, with different shapes, such as, cereal, flake, animal, star etc.

Flow chart

Raw material formulating → Mixing → Extruding, inflating cutting into ball shape → cooling conveying → Air conveying → tablet compressing → Drying → Flavoring → Conveying → Drying → Cooling conveying → (Packing)

Corn Flakes Production Line/Breakfast Cereal Production Line

Equipments allocation

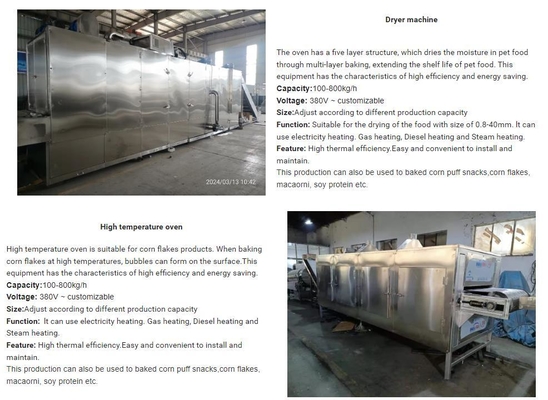

Mixer → SLG70/85 extruder → air conveyor → flaking machine →air conveyor → Three-layer oven → elevator → salt cooking machine →sifter → elevator → flavor roller → melting machine → sugar sprayer( air compressor) → elevator → five-layer oven → cooling conveyor → (wrapping machine)

![]()

1.CORN FLAKES PRODUCTION LINE is a very popular equipment line.It takes corn flour as main raw material, it is very crispy after extruding,

granulating,flaking,frying, seasoning.The outstanding characteristic of flakes is containing abundant compound carbohydrate and dietary fiber.

We can also add some trace elements and minerals.

2.A GENERAL VIEW of CORN FLAKES PRODUCTIN LINE Including Mixing and Extrusion System, Flaking system, Drying system,

Inflating system, Flavoring, drying and cooling system.Square for work shop: 3000m2 and 4.0m high

3.PROCESSING CHART of CORN FLAKES PRODUCTION LINE

Mixer--Screw conveyor—Conditioner--Twin screw extruder--Cooling conveyor--Air conveyor--Flaking machine--Air conveyor--Multi-Layer Oven—

Hoister--Salt cooking machine—Sifter—Hoister--Sugar melting machine-- Sugar sprayer--Air compressor—Roller—Hoister—Oven--Cooling conveyor