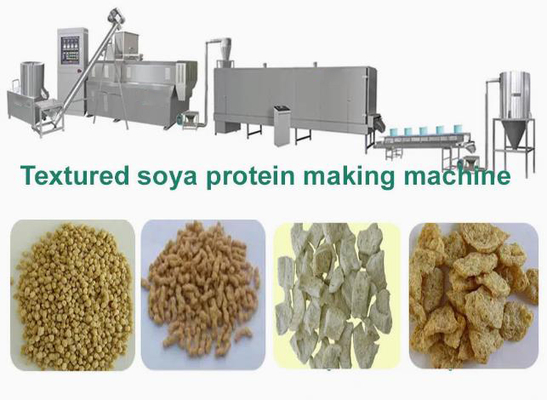

Textured Soya Extruder Machine / soya nuggets extruder Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-65/70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Product Name: | Corn Flakes Production Line | Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. |

|---|---|---|---|

| Condition: | New | Layout: | AutoCAD Format According To Client’s Workshop |

| Manual: | English Version | Standard: | CE |

| Highlight: | dog food extrusion machine,dog food extruder machine |

||

Product Description

Textured Soya Extruder Machine / soya nuggets extruder Production Line

![]()

Main Machinery

We are a professional food machines manufacturer in ANYANG City, China. We have much

experience in Extrusion snack food processing, including Directly puffed snack food

machine, Shaping and core filled snack food machine, Fried Crispy snack food machine,

Popular Breakfast cereal Corn Flakes machine, Baby food machine, TVP/TSP machine,

Modified Starch machine, Dog food machine and Fish food machine etc.

![]()

Reputation

We have locked 70% share in the snack food market all over the world and exported many

countries, like USA, Mexico, Brazil, New Zealand, Uzbekistan, India, Saudi Arabia, Ethiopia,

Uganda, South Africa, Germany etc.

Strength

Our exceptional engineering team can guarantee customers’ quality machine which can be up

to design requirement and perfect working state. Our technician can also provide all kinds

of relevant technology to make food healthy and safe.

Features of Extruder Production Line Cereal/Corn Flakes Processing Line

1. High out: 100-500 kg/h, with different configuration equipment.

2. Stable performance, low noise, low energy consumption

3. It has self-cleaning function, save labor and time, no need to disassemble the equipment.

4. Auto-self control temperature system.

5. Twin screw, Alloy steel material

6. Stainless steel material

Equipments Components of cereals/corn flakes processing line

1. Flour Mixer For mix the raw material such corn flour, starch, rice flour etc.

2. Conveyor For conveying the material to the extruder machine

3. Twin Screw Extruder For extruding the raw material

4. Corn Chips Cutter or Shaper (sheeter) For making shape of the extruded food

5. Conveyor For conveying the puffing food to the next step

6. Oven For dry and baked the puffing food

7. Seasoning Machine For adding flavor for you puffing food

Technical Parameters

![]()

|

Model |

Installed Power |

Power Consumption |

Output |

Size(L×W× H) |

|

MK65 |

275kw |

193kw |

120-150kg/h |

39000x1200x2200mm |

|

MK70 |

282kw |

197kw |

200~300kg/h |

41000x1500x2200mm |

![]()

![]()