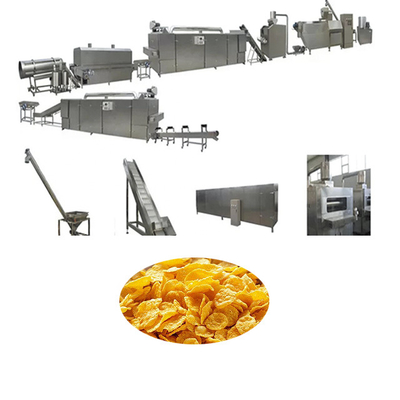

Cereal Corn Flakes Making Machine Snack Processing Line Siemens PLC Touch Screen

Product Details:

| Place of Origin: | China |

| Brand Name: | Mikim |

| Certification: | CE & ISO |

| Model Number: | MK-70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 70000-USD 100000 |

| Packaging Details: | wooden case, which is suitable for long-distance transportation, multi-time loading & unloading for fork trucks. |

| Delivery Time: | 45 working days after received your payment |

| Payment Terms: | L/C, T/T, Western Union, D/P |

| Supply Ability: | 20 sets per month for roaster |

|

Detail Information |

|||

| Name: | Corn Flakes Machine | Whole Line's Dimension: | 45 X 5 X 3m |

|---|---|---|---|

| Certificate: | CE & ISO | Material: | Made By Stainless Steel 304 |

| Layout: | AutoCAD Layout As Client's Workshop | Manual: | English |

| Advantage: | Complete Circle For Production Of Corn Flakes, Which Has Regular Shapes And Tasty Taste | ||

| Highlight: | corn flakes making machine,rice flakes making machine |

||

Product Description

Cereal Corn Flakes Making Machine Snack Processing Line Siemens PLC Touch Screen

Corn Flakes Production Line

Corn Flakes Making Machine produces corn flakes, breakfast cereals, and puff snacks similar to Kellogg and Nestle products, the shapes and sizes can be various. Two capacity can be made: 120-150kg/hr, and 250-300kg/hr.

Raw materials

corn flour, rice flour with liquid and other additives could be used as raw materials.

Commissioning Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After receiving confirm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line..

5. Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer’s detailed formula.

6. It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

![]()