Breakfast Cereal Bar / Corn Flakes Processing Line SS304 with CE Standard

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-65/70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, |

| Delivery Time: | 45 working days after received your payment |

| Payment Terms: | T/T or L/C, Western Union |

| Supply Ability: | 30 sets per year |

|

Detail Information |

|||

| Product Name: | Automatic Cereal Breakfast Corn Flakes Production Line/corn Flakes Processing Machine/pop Corn Machinery | Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. |

|---|---|---|---|

| Material: | SS304 | Condition: | Continuous & Automatic |

| Layout: | AutoCAD Format According To Client’s Workshop | Manual: | English Version |

| Standard: | CE | Guarantee: | 12 Months |

| Highlight: | corn flakes processing line ss304,breakfast corn flakes processing line,breakfast corn flakes production line |

||

Product Description

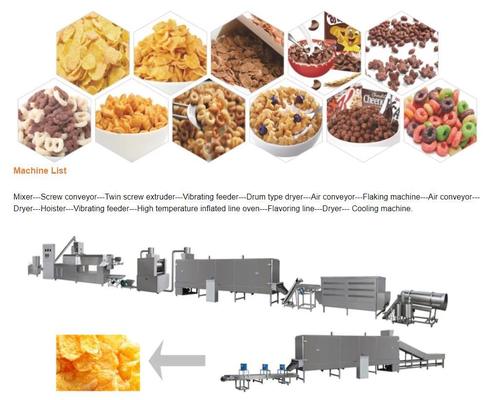

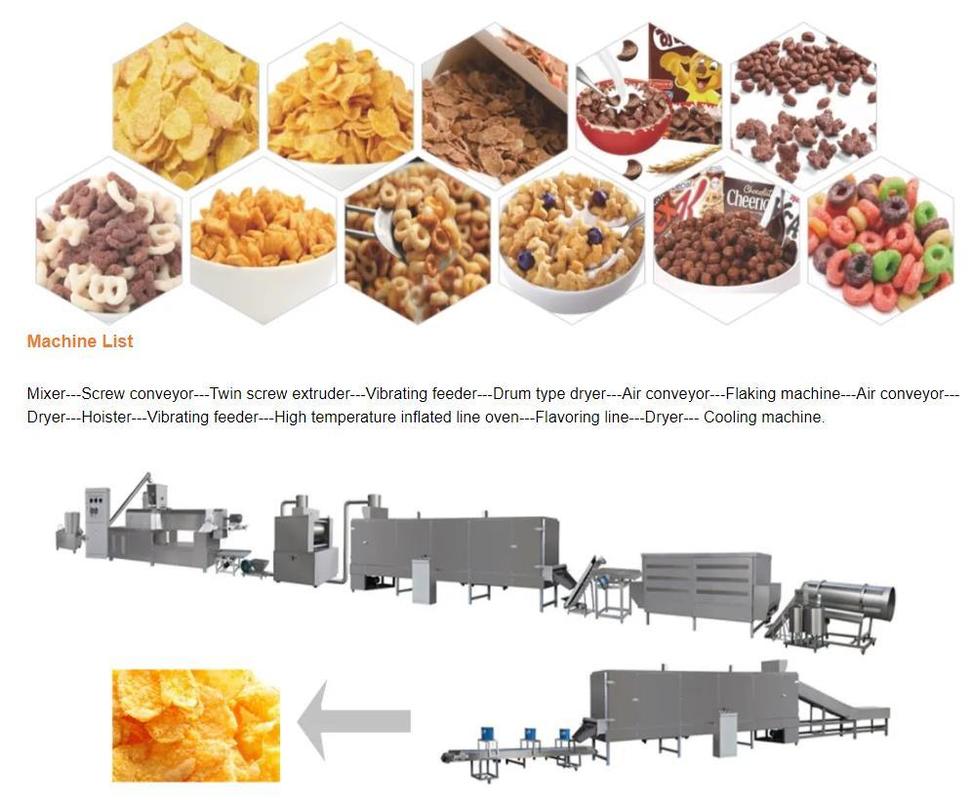

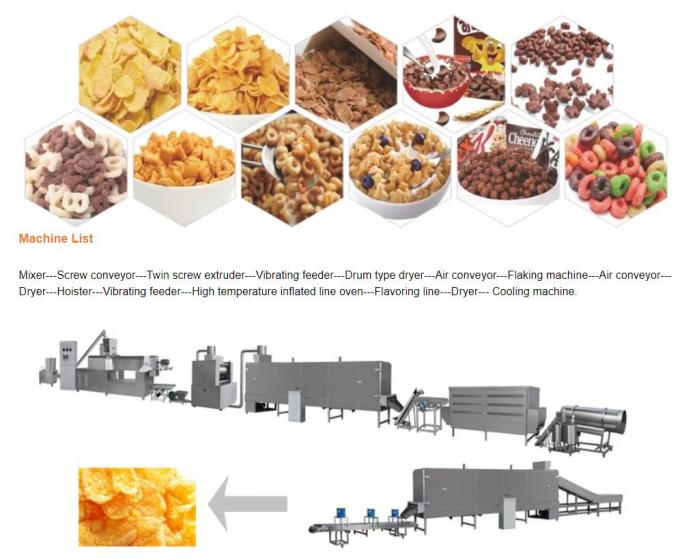

Breakfast Cereal Bar / Corn Flakes Production Line/corn Flakes Processing Line

1. Description

It is mainly made from corn powder and form very cute ring shape after extrusion. It is a new choice for your breakfast after mixing with milk. Designed as a kind of breakfast cereal, it is crunchy taste and water resisting property make you have something in mouth for chewing, but not hard. To make cute rings, our company has three types production lines by capacity 150kg/hr

a. Raw materials: adopts corn flour as raw materials

b. Products: This line can be used to produce corn flakes

c. Capacity: 150kg/h, 260kg/h for corn flakes; 150kg/h, 260kg/h and 500kg/h for breakfast cereal

d. Flow chart: Mixing system---Extrusion system---Cooling system---Flaking system---Drying system---Toasted system---Sugar Spraying system---Drying system--- Packing system

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

f. Machines Materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

2.MK-65-III Double Screw Extruder serves to gelatinize flours and starches continuously and automatically. After dosing, the materials are worked by two co-rotating screws composed by sectional modules for the following functions: forward and backward transport, mixing, de-gassing, cooking and forming.

| 1.The inside structure is made by painting steel, but all the parts touching with the raw material or products are made by SUS304; |

| 2. A wide range of pet food with different formulations can be obtained for dog, cat, bird, fish, rabbit, turtle, etc.; |

| 3.The use of a continuous automatic process provides greater production outputs than offered by traditional systems, with savings in energy and reduced management cost; |

| 4.Using PLC and touch screen to control the extruder, having friendly and clear interface; |

| 5.Automatic dosing unit for utilization with any type of flours and starches (flour size should be 60-80mesh); |

| 6. The screws are made by 38CrMoAIA with the hardness of 55hrc, which is hard and strong; |

| 7.Barrel is divided into 3 parts and made by alloy steel with hardness 55hrc. |

| 8.The barrel and the screws are modular in structure. Each module is equipped with its own thermoregulation ring with electric heating rings; |

3.Features:

(1). The corn flakes machine has the advantage of rational design, high automatic degree and accuracy control.

(2).The main body material is stainless steel, which is easy to be cleaned.

( 3).The screws material is 38CrMnAl, which is wear-resisting.

(4).Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

(5).The temperature and rotating speed can be controlled and adjusted .

4. High Reputation Among Our Customers

At present, Our Company locks in 70% market share in China, and our products have been selling well to more than 90 countries like Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South America, Middle East, Africa and other countries or regions.

We hope to establish good and long term friendly business relationship with more clients all over the world in the future.

5. About US

MIKIM is a professional food machinery manufacturer in China. An exceptional engineering team, personal customer service center and high-quality manufacturing capabilities have evolved exponentially since our humble beginnings in 2004, making us one of the preeminent providers of reliable extrusion equipment world-wide. We can guarantee customers superior quality machines up to design requirements and perfect working state. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

Machinery has its own manufacturing plants workshops in China, business scope covering mainly machinery and equipment for corn meal milling system, corn flakes & breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system, soy nuggets system; as well as pet food/fish food system.

Machinery engages in the technical research of extrusion foodstuff, in order to let our clients have superior foodstuffs to sell in the market. We can improve client's equipment and provide related training on new advanced technique. We can also make special designs for special products and materials according to clients' special requirements.