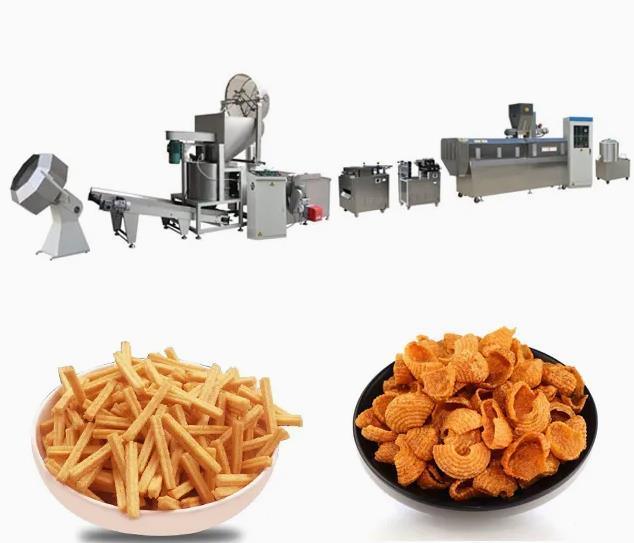

Single Screw Snack Extruder Machine For Pasta Macaroni , Pasta Extruding And Roaster Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Mikim |

| Certification: | CE ISO |

| Model Number: | MK-100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD7000~66200 Per set |

| Packaging Details: | wooden case, which is suitable for long-distance transportation, multi-time loading & unloading for fork trucks. |

| Delivery Time: | 50 working days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Name: | Pasta Roaster | Space Needed: | 30 X 5 X 3m |

|---|---|---|---|

| Certificate: | CE ISO | Material: | Made By 304 Stainless Steel. |

| Layout: | AutoCAD Layout As Client's Workshop | Manual: | English |

| Processing Type: | Extrusion | ||

| Highlight: | single screw snack extruder machine,pasta snack extruder machine,pasta corn puff extruder machine |

||

Product Description

Single Screw Extruder For Pasta Macaroni , Pasta Extruding Machine

![]()

Detailed product description

Pasta processing line

Single-screw extruder

Pasta production line

We invite you to the innovation processes concerning "Macaroni". The lines have always been characterized by their innovative technical solutions and their high degree of reliability. Macaroni Processing Line is for macaroni, fusilli, penne, conchigile production by single-screw extruder. The raw material can be durum, maize starch, potato powder, potato starch, cassava starch or their mixture, etc. The pellet can by different shapes, like shell, spiral, square tube, etc. Pasta and macaroni are a semi-manufactured dry product, made of dough, cooked opportunely using extrusion cooking technology, shaped and formed until reaching a humidity of less than 12%. This semi-manufactured product is extremely compact, (apparent density of 300-400 g/l, 10 times higher than that of the finished product) occupies little space and can be easily preserved for over a year in normal environment conditions, without particular packaging. The macaroni can be fried or cooked by customers in their own kitchen.

| Name | Description |

| Flour Mixer |

Flour Mixer is used to mix the raw material, like corn flour, rice flour with liquid and other additives. |

|

Screw Conveyer |

Screw Conveyer is used to the mixed materials to the feeder of the extruder. |

|

DR-65 Double Screw Extruder |

MK100 Single Screw Extruder serves to gelatinize flours and starches continuously and automatically. After dosing, the materials are worked by two co-rotating screws composed by sectional modules for the following functions: forward and backward transport, mixing, feeding of additives, injection of liquids, de-gassing, cooking and forming. |

|

HQS Pulling & Cutting Machine |

HQS Pulling & Cutting Machine is for the cutting of tube shape pellets. |

|

Big Hoister |

Big Hoist is a conveyor, which is used to convey the raw materials into the seasoning drum. |

|

Five-Layer Roaster |

MK-65 Roaster is used to dry a wide range of products, such as snacks, corn flakes, core filling food, etc |

|

Cooling Conveyer |

Cooling Conveyer can well cooling the snacks, and convey the snacks to the packing machine. |

Raw materials:

like corn flour, rice flour with liquid and other additives

![]()

Commissioning Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After receiving confirm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line..

5. Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer’s detailed formula.

6. It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

![]()