Stainless Steel Snack Extruder Corn Flakes Making Machine Price For Cereal Maize Flakes

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-65/70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Product Name: | Stainless Steel Snack Extruder Production Line For Cereal / Corn Flakes | Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. |

|---|---|---|---|

| Condition: | New | Layout: | AutoCAD Format According To Client’s Workshop |

| Manual: | English Version | Standard: | CE |

| Highlight: | cereal corn flakes making machine cost,cereal corn flakes making machine price,stainless steel corn flakes making machine cost |

||

Product Description

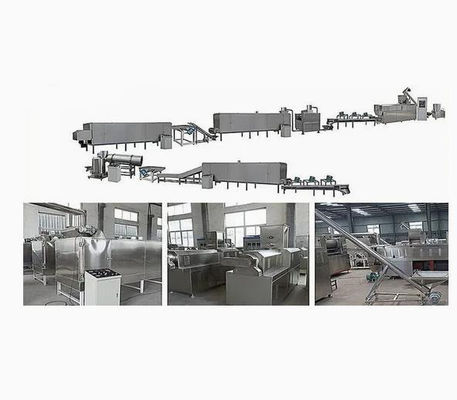

Stainless Steel Snack Extruder Production Line for Cereal / Corn Flakes

![]()

Introduction of cereals/corn flakes processing line

Allance machinery specialize in manufacturing extruder machine (bulking machine or puffing machine).

We mainly supply single extruder machine, twin-screw/single-screw extruder machine, pet food equipments, soybean tissue-albumen processing line, corn flakes, nachos, crisp food production line.

And our production line adopts corn flour, starch, rice starch, soybean and other grain as raw material, can make various shapes corn flakes, chips, nachos, tortilla, crispy bugles corn puffs, corn curls and many other snacks food. The final snack food can be made into pellet, slice or animal shapes.

As the bulking snack food is more and more popular in the world, we believe that the snack food machine will have a good future.

We can according to your requires change the equipment configuration to satisfy your different production need.

Features of Extruder Production Line Cereal/Corn Flakes Processing Line

1. High out: 100-500 kg/h, with different configuration equipment.

2. Stable performance, low noise, low energy consumption

3. It has self-cleaning function, save labor and time, no need to disassemble the equipment.

4. Auto-self control temperature system.

5. Twin screw, Alloy steel material

6. Stainless steel material

Equipments Components of cereals/corn flakes processing line

1. Flour Mixer For mix the raw material such corn flour, starch, rice flour etc.

2. Conveyor For conveying the material to the extruder machine

3. Twin Screw Extruder For extruding the raw material

4. Corn Chips Cutter or Shaper (sheeter) For making shape of the extruded food

5. Conveyor For conveying the puffing food to the next step

6. Oven For dry and baked the puffing food

7. Seasoning Machine For adding flavor for you puffing food

Technical Parameters

|

Model |

Installed Power |

Power Consumption |

Output |

Size(L×W× H) |

|

MK-65 |

275kw |

193kw |

120-150kg/h |

39000x1200x2200mm |

|

MK-70 |

282kw |

197kw |

200~300kg/h |

41000x1500x2200mm |

Packing Type:

Wooden packing

Certificate:

CE certificate for this plant.

Terms of Payment:

30% should be paid by T/T as deposit, 70% balance should be paid by T/T before delivery.

Testing & training:

If the machine is exported to other countries, the buyer should be responsible for the round-air tickets, local transportation, board & lodging.

Warranty:

The seller guarantees the quality of the products for 12 months since the date of installation. During the warranty period, any problems/defaults happen on the hard parts of the machinery, the buyer will replace the parts at the seller’s cost (FREE). If the defaults are aroused by the defaulted operations, or the buyer needs the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.