200-500kg Kellogg Roasted Breakfast Cereal Corn Flakes Processing Line Snack Food Extruder Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE ISO9001 |

| Model Number: | MK-65/70 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Product Name: | 200-500kg Kellogg Roasted Breakfast Cereal Corn Flakes Snack Food Extruder Machine | Application: | Produces Corn Flakes, Breakfast Cereals, And Puff Snacks Similar To Kellogg And Nestle Products, The Shapes And Sizes Can Be Various. |

|---|---|---|---|

| Condition: | New | Layout: | AutoCAD Format According To Client’s Workshop |

| Manual: | English Version | Standard: | CE |

| Highlight: | cereal corn flakes processing line,breakfast snack food extruder,breakfast corn flakes processing line |

||

Product Description

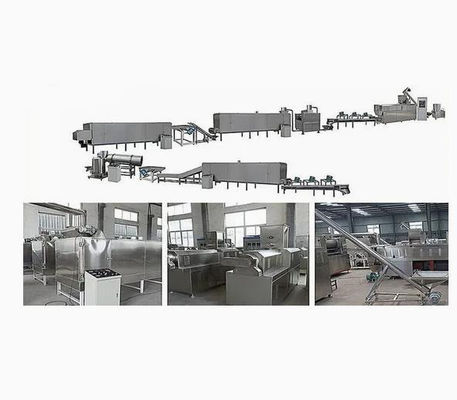

200-500kg Kellogg Roasted Breakfast Cereal Corn Flakes Snack Food Extruder Machine

![]()

Brief introduction:

Corn flakes processing line is one kind of crispy foods, adopting grist as basic materials.

It is fast and nourishing food with given structure, such as granule shape, flake shape and

animal shape. Its outstanding characteristic is containing abundant compound carbohydrate

and meal fiber. It can be added with cocoa and sugar, such as honey and maltose. You can

enjoy it directly by mixing with coffee, milk, ragout or functional drink. Children can have

breakfast of sweet crispy snack.

Corn Flakes Processing Line is a continuous and economical process with an easily

controlled production cycle. The use of a fivelayers roaster in cereal flakes production allows

to change cooking conditions in function of different raw materials, in order to make the line

quite versatile and capable to give final products the best blister effect.

A finished product having long lasting crispness in milk due to minimal damage of the cereal's starch structure during processing thanks to the particular process conditions. An end product exhibiting the best combination of texture, colour and flavour base on an accurate control of the conditioning, drying and toasting stages of the process. Unlimited choice of shapes and formulae for shaped cereal such as stars, crispies, pillows, rings, stars etc. Simple and fast possibility of intercombing the two over mentioned lines, in order to obtain the widest range of products with minimum expense.

Technical process:

1 Raw material mixer 2 twin screw Extruder 3 shaking cooler 4 air conveyor 4 Presser 5 three layers Oven 6 air heater7 sugar sprayer8 dryer 9 cooler

Technical Parameters

|

Model |

Installed Power |

Power Consumption |

Output |

Size(L×W× H) |

|

MK65 |

275kw |

193kw |

120-150kg/h |

39000x1200x2200mm |

|

MK70 |

282kw |

197kw |

200~300kg/h |

41000x1500x2200mm |

![]()