Energy Saving MK-65 Bar Forming Machine with CE Approved

Product Details:

| Place of Origin: | henan |

| Brand Name: | Mikim |

| Certification: | CE Certificate |

| Model Number: | MK-65 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD 28000~ USD 35000 |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 45 working days after receiving the down payment |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Application: | Cereal Bar Machine | Voltage: | Customerized |

|---|---|---|---|

| Power: | 88kw | Weight: | 1500kg |

| Warranty: | 12 Months | Material: | SUS304 |

| Layout: | Auto CAD Format | ||

| Highlight: | snacks making machine,cereal bar making machine |

||

Product Description

Energy Saving MK-65 Bar Forming/Molding Machinery with CE Approved

![]()

Introduction

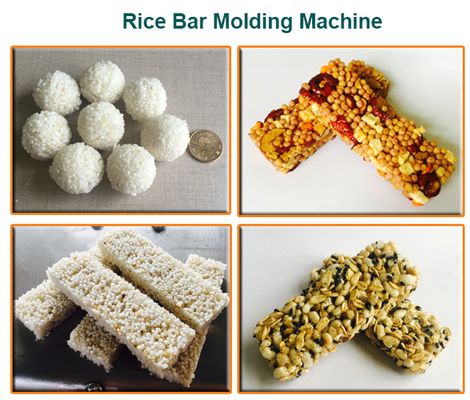

1. It can make different shapes, such as ball, round bar, square, and so on;

2. Mechanical soft pressure will not damage nut particles with more elegant molding. Direct mold pressing and molding can be free from rework, which saves materials cost and waste;

3. The whole machine is in mechanical transmission instead of the pneumatic pump; positioning is precise, the upper and low mold coordinates each other tightly and the molding effect is excellent;

4. Converter with high performance is equipped, which makes speed regulating more convenient, efficiency high, and performance stable; 24-h successive production in high speed is accessible;

5. All the molds and hoppers have been conducted with anti-stick disposal;

6. All the links contacting the goods are the nonpoisonous and harmless materials which are oil and high-temperature resistance;

ISO9001 Certificated Quality Cereal Bar Equipment/Machine/Making Machine/Machinery can produce all kinds of shapes of cereal bars with the raw material of rice, millet, wheat, highland barley, Fagopyrum tartaric Gaertn, maize, broomcorn, Chinese pearl barley, buckwheat, etc.

Certificate

CE CERTIFICATE provided, which strictly meets CE standards and EU country's import policy.

ISO 9001 CERTIFICATE is provided, which strictly meets ISO 9001 standards.

Processing Procedure

MK-65 Cereal Bar Forming Line can produce all kinds of shapes of cereal bars with the raw material of rice, millet, wheat, highland barley, Fagopyrum tartaric Gaertn, maize, broomcorn, Chinese pearl barley, buckwheat, etc.

Working Procedures: Making pop-rice - Melting sugar - Mixing sugar with pop-rice - Forming cereal bar - Packing.

Advantages

ISO9001 Certificated Quality Cereal Bar Equipment/Machine/Making Machine/Machinery, the shapes can be round, cylindrical, square, semi-round, triangular and blossom, etc.

Mechanical pressing & rubbing does not hurt nuts, without waste.

ISO9001 Certificated Quality Cereal Bar Equipment/Machine/Making Machine/Machinery mechanical driving, accuracy positioning, upper and nether molds tight fit, makes super cereal bar shaping.

Using a high-performance frequency inverter, easy-adjust speed, and high efficiency, it can produce 24-hour continuously.

ISO9001 Certificated Quality Cereal Bar Equipment/Machine/Making Machine/Machinery, molds and hopper are both non-sticky processed. All the parts may contacts food are all non-toxic material, oil, and high-temperature resistance.

The cooling conveyer can be customized as demand.

Technical Parameters

| Output | Installed Capacity | Voltage / Frequency | Dimension |

| 300kg per hour | 88kw | Customerized | 11 x 4 x 2m |

Key Equipment Show

![]()

![]()

![]()

![]()

![]()

![]()

Commissioning & After-sales Service

1. We make accurate factory layout design according to the customer’s factory size; if the customer needed, we could make a workshop design with electricity power, water supply, gas power, material storage, final storage, worker’s restroom, etc.

2. After delivering machines to the client’s factory, we start to apply for the Visa to the client’s country

immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. When the machines arrive at your factory, our engineers are ready to start the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production in the shortest time.

4. Our engineers have a responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning service, and we supply a 1-year guarantee from the date of completion of the commissioning service.

6. The engineer’s round-trip flight tickets, accommodation, and daily salary of USD 100 are on the client’s account.