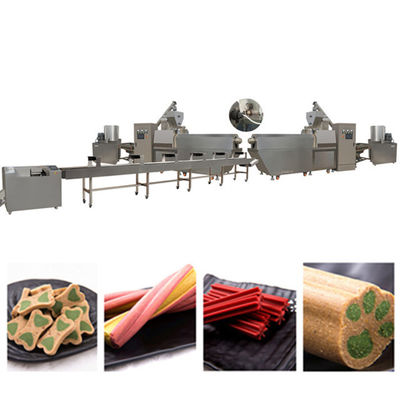

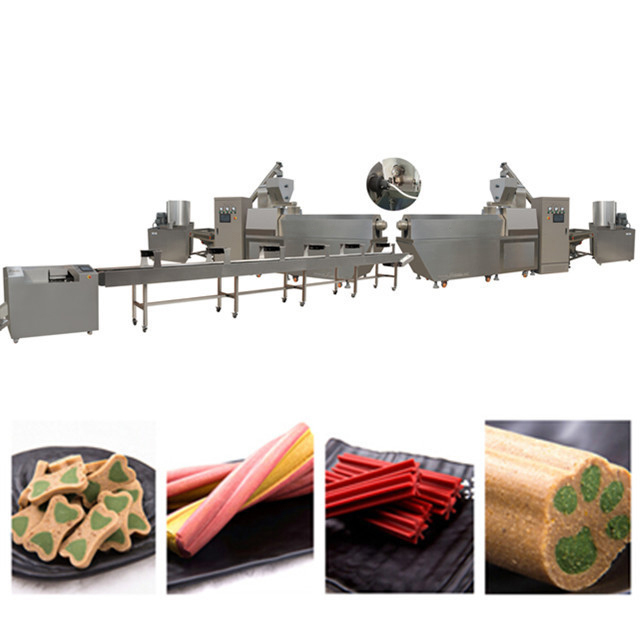

MK-100/MK-300 Semi wet Pet dog treats / Dog dental chews food extruder machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE Certificate |

| Model Number: | MK-100/MK-300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 sets |

|---|---|

| Price: | USD 28000~ USD 35000 |

| Packaging Details: | We could supply Export Standard Wooden Case, suitable for long trip and loading & unloading. |

| Delivery Time: | 45 working days after receiving the down payment |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 Sets per year |

|

Detail Information |

|||

| Condition:: | New | Model Number:: | MK-100/MK-300 |

|---|---|---|---|

| Application:: | Dog Snacks/ Pet Treats | Brand Name: | MIKIM |

| Material: | SUS304 | Motor: | WEG Motor With 3 Year Warranty All Over The World |

| PLC & Touch Screen: | Simens | Electric Parts: | ABB Or Schneider |

| Highlight: | pet extruder machine,dog food making machine |

||

Product Description

Top quality MK-100/MK-300 semi wet Pet dog treats/Dog dental chews food processing line/extruder machine

Pet Chew Food processing line are the all-automatic and food grade processing line. You can make any shape of the pet food according to different market requirements.

In order to increase the protein and other nutrients for our pet,Automatic dry dog pet food machine/processing line use meat powder,grains,beans and vegetables as raw materials to produce pet food with new shape, unique taste to let them live healthie

1. Mixer blending all ingredients like corn flour,soybean flour, fish meal, bone/meat meal, water according to the accurate formula to make dry floating & sinking fish feeds , pet dog cat feed pellets with various daimeter 1mm, 1.5mm, 3mm, 5mm, 8mm, 10mm, 15mm, 20mm, etc.

Fish Feed Pellets Floating Time: 24 hours after baked dry completely with oil coated, also healthy for fish body growing, especially for salmon tilapia,catfish,trout,etc

2. Extrusion will male all materials cooking extrusion under the high temperature & pressure insde of the extruder barrel, with twin-screw high speed rounding. Then shaping the feeds into the fixed shape .

3. Drying processing we make sure every single feed pellets completely dry with our drying ovens which has the specially design hot air recelying system, supports electric/oil/gas/steam power resource type only suitable and cost saving for your local power conditions.

4. Flavoring line can be supply the feeds with oil , healthy for fish or other animals digestive absorption

Also can be added some other vitamins, minerals.

5.Cooling & packing, our package machine can be various 0.5-50kg/bag, range packing weight for your different markets needs, longer shelf life for final feed prodcuts.

![]()

1. Good quality product with reasonable price.

2. Fast response to all your questions.

3. Low MOQ, Customation welcome.

4. Fast Delivery.

Packing: inside plastic bag, outside wooden case for core filling snack food puffed food making machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, or upon clients' demands.

1. Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

2. During Production: Timely updates the machine status for customer to ensure delivery time, and quality

3. After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

4. Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

5. Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.

6. After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts;

1.Technical Parameter

| Model | MK-100 single screw extruder | MK-300 single screw extruder |

| Installed capacity | 38kw | 54kw |

| Power consumption | 28kw | 30kw |

| Output | 100-150kg/a | 200-250kg/h |

| Size | 12000*1200*2000mm | 13000*1200*2000mm |

2.Introduce:

Dog chewing food machine can make dog chewing food is made of many kinds of different materials with

scientific configuration and extrusion in the extruder. This kind of product can be made into a variety of

shapes such as stick, bone, etc. This kind of food not only provides nutrition to dogs, like protein, fat, vitamin,

etc, but also satisfies the dog nature hobby, benefits its strong teeth, cleans mouth and teeth, and prevents

disease.

3.Materials: adopts corn flour, bone meal, fish meal as raw materials

4.Capacity: 100kg/h 200kg/h

5.Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

6.Process and follow chart

Mixer---Screw conveyor--- Single screw extruder---Cooling machine---Cutting machine--- Hoister

7.Technical Parameters

| Model | Capacity | Power | Dimension | Worker needed |

| MK-100 | 100-150kg/hr | 81kw | 18x5x3m | 2-3 |

| MK-300 | 200-260kg/hr | 95kw | 20x5x3m | 2-3 |

8. Payment term:

1. 40% of total payment as the deposit,we will finish the machine within 40 days.

2. 60% of total payment before making delivery the Equipment to Buyer’s plant.

Package: Wooden case for export, fit for multiple handing and long distance marine shipping.

Delivery time: Seller should get all the goods ready and ship the goods to the destination port within 40 days after receiving the total amount price.

Quality guarantee terms: equipment shall be guaranteed 12 month, without destroyed by some people. Enclosed the whole line, we will give you some spare parts, such as heating ring, spanner, etc. for free. The spare parts shall be supplied at preferential price for an extended long time.

Installation and training: we will send our engineer to install and train in your company, on condition that you should supply the go and return air tickets, the accommodation, the food for our engineers and also pay USD50 each person per day.