Twin screw extruder baby milk rice powder making machine with CE ISO certificated

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Mikim |

| Certification: | CE |

| Model Number: | MK-65/70/85/90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard export wooden cases, wrapped with film firstly, then packed with strong wooden cases, which are suitable for long-term trip and multi-times loading & unloading by trucks. |

| Delivery Time: | 30 working days after received your payment |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50 sets per year |

|

Detail Information |

|||

| Condition: | Continuous & Automatic | Dimension(L*W*H): | 2150*1500*2300 |

|---|---|---|---|

| Voltage: | 380v, 50hz, 3phases (adjustable) | Warranty: | 12 Months |

| Applied: | Nutrition Powder Extruding Line | Material: | SS304 |

| Manual: | English Version | ||

| Highlight: | rice powder making machine,baby food making machine |

||

Product Description

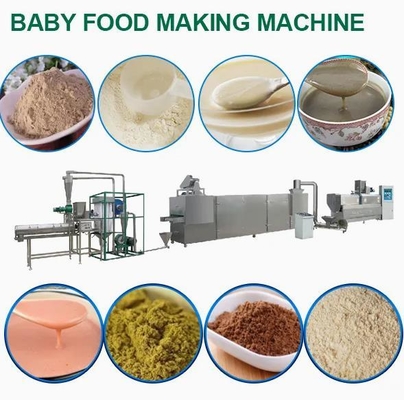

Twin screw extruder baby milk rice powder making machine with CE ISO certificated

![]()

For the Mung processing equipment has advantage of high degree automation and energy saving.

It can use broken mung and other cereals as raw materials.

After strengthen mixed with a variety of vitamins,proteins and minerals,and extruded,mixed and cured in extruder,it became to a half of mung again.

The usage is same to natural mung,but more semple and convenient than before. It not only nutrition but also adapts to the fast rhythm of the modern life.

Artificial mung is produced by twin-screw extruder.

When it comes to Indian cuisine, from pizza to mung beans, whole beans and shelled mung beans are all popular choices. In regions such as Karnataka, Maharashtra, Gujarat, Kerala, and Tamil Nadu, people cook whole mung beans to make dried products such as mung bean curry, as well as stews and mung beans. The origin of mung beans is in India and Myanmar. The crushed mung bean powder is processed and expanded into half a mung bean using a 75 twin-screw extruder. Mung beans can be used to make delicious Sabut Moong Dal, mung bean curry, Pesaratto pizza, spinach mung bean pancakes, and more

Features & Advantages

- There's no any wastage or material leak in the whole production procedure.

- Nutrition Powder Extruding Line is automatic processing line, and easy control.

- The nutritional substance such as Vitamin can be added to make sure the enough nutrition for babies.

- Different recipes can be made to meet various market requirements.

- The production period is short and production cost is low.

- Children's nutrition powder, black sesame paste and other nutrition powder are all the final products.

Technical Parameters

|

Model |

Capacity |

Power |

Dimension |

|

MK-65 |

120-150kg/hr |

75kw |

20 x 5 x 3m |

|

MK-70 |

200-260kg/hr |

90kw |

22 x 5 x 3m |

![]()

![]()

![]()

Fully automatic nutritional baby rice powder manufacturing line

Brief introduction of nutritional baby rice powder extruding machine /processing line:

- Nutrition baby rice powder extruding machine is used to produce infant baby rice powder ,sesame paste ,beans powder and some other instant flour products.

- Its raw material can be corn ,rice,beans and other kinds grains.This can finish all the process automatically from the feeding to the end products ( rice powder etc).

- PLC control panel ,easy to operate,no leak of powder dust,sanitation.

- And also easy to add all kinds of nutritional elements powder in it by our ribbon mixer to get nutritional rice powder.

1. Raw material : corn rice etc

2.Products : all kinds of extruding powder products.

3.Capacity:100-150kg/h 200-250kg/h 350-500kg/h 800-1000kg/h

4.Process flow chart : mixer→extruding→drying→grinding

5.Voltages: Three phases: 380V/50HZ, Single phase: 220V/50HZ, also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

![]()